First I sanded the finish off and down to solid wood.

It’s a 1955 14 ft model. I saturated the rot areas with West System Epoxy.

Then I made reinforcement marine plywood for both sides and bedded them in epoxy putty. I added fillets of PL500 Construction Adhesive.

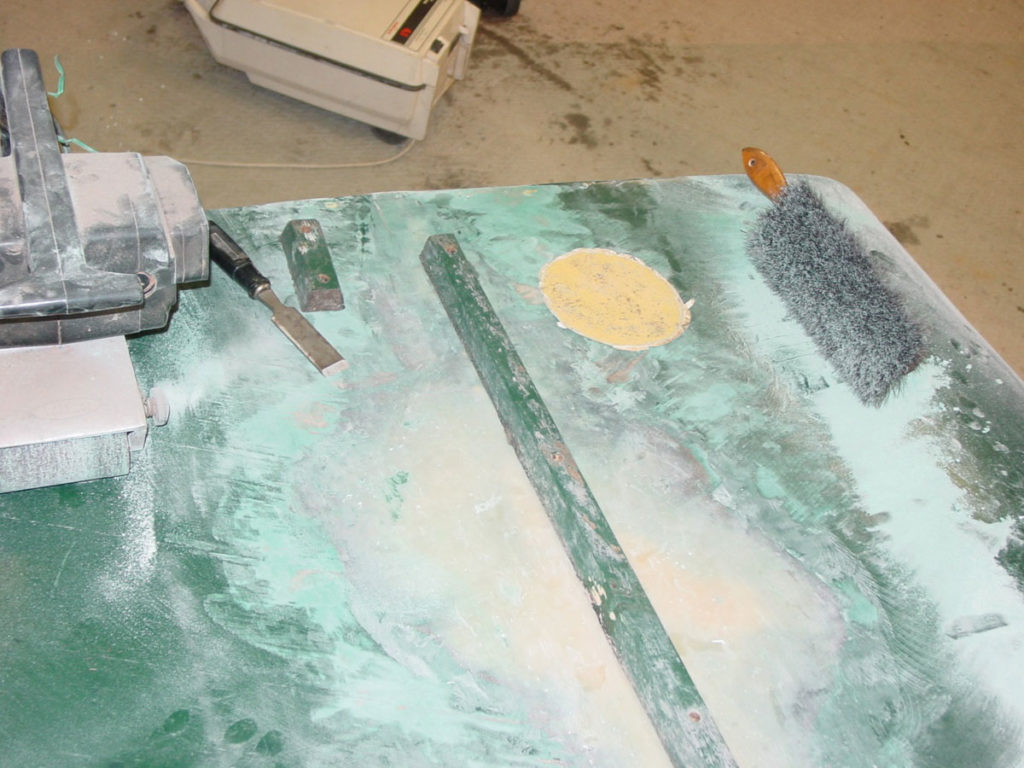

With the boat turned over the outer keel was removed and all the soft areas were sanded on the outside

This is what it looked like before sanding. At this point Cheryl washed the bottom of the boat

Sanding back to good wood with an 8 inch 40 grit disc exposed the penetrations from the other side, now this side was penetrated with the thin West System Epoxy

Next a blob of 2 part of epoxy putty is mixed. I clamp the mixing board to table because it is so thick

Putting the putty in place

Neatly spreading to fill all the holes and cavities. Several applications were required

The belt sander helped to produce a smooth flat finish.

After sanding with the disc, I sanded with a belt sander. The outer keel was fitted and screw holes drilled. Then the keel was installed using the same putty adhesive

Be the first to comment